The Client

Specialty Chemicals Manufacturer

Capabilities Demonstrated

- Remote FAT

- Plant automation simulation

- Batch-process automation

- Multi-plant interaction

Challenge

A major specialty chemicals manufacturer located hundreds of miles away had been working with A&E as a customer for many years. This customer originally selected A&E due to the specialized nature of their work (as a general local industrial automation integrator wasn’t going to cut it).

The pros of A&E’s expertise within batch processing automation made the cons of travel worthwhile. However, the travel aspect was a point of inefficiency, and the customer did have interest in improving this.

The tipping point came into play during the 2020 pandemic (COVID-19). A&E was in the midst of a programming controls automation changeover with this customer when businesses started going into lock-down.

The customer still needed their new control system, but now needed to maintain physical distancing. The customer looked to A&E to help keep this project moving.

Solution

The solution enabled remote factory acceptance testing (FAT) of the batch automation system that A&E had developed for the customer.

Benefits

- Enabled physical distancing

- Reduced travel – the customer didn’t need to send a team to the integrator’s site for FAT

- Reduced setup costs – no need to set up a FAT room with test computers and screens

- Increased schedule flexibility – the customer was able to test on their schedule instead of having to block out days or weeks at a time for travel

- Reduced the schedule via parallel work – A&E was able to continue working on other aspects of the project during the test cycle

- The customer was able to begin testing quickly – they logged in and started testing, allowing for greater flexibility with testing schedules

- Intellectual property was isolated by using a gear network

System Overview

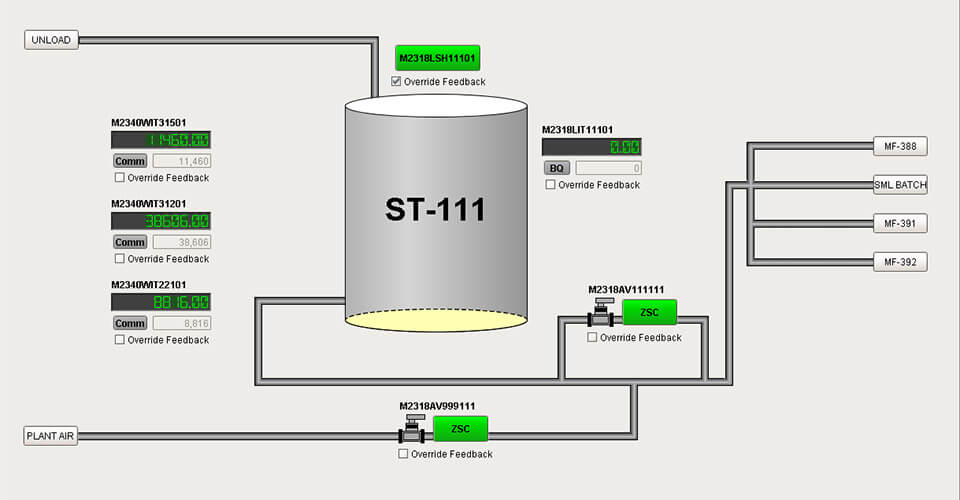

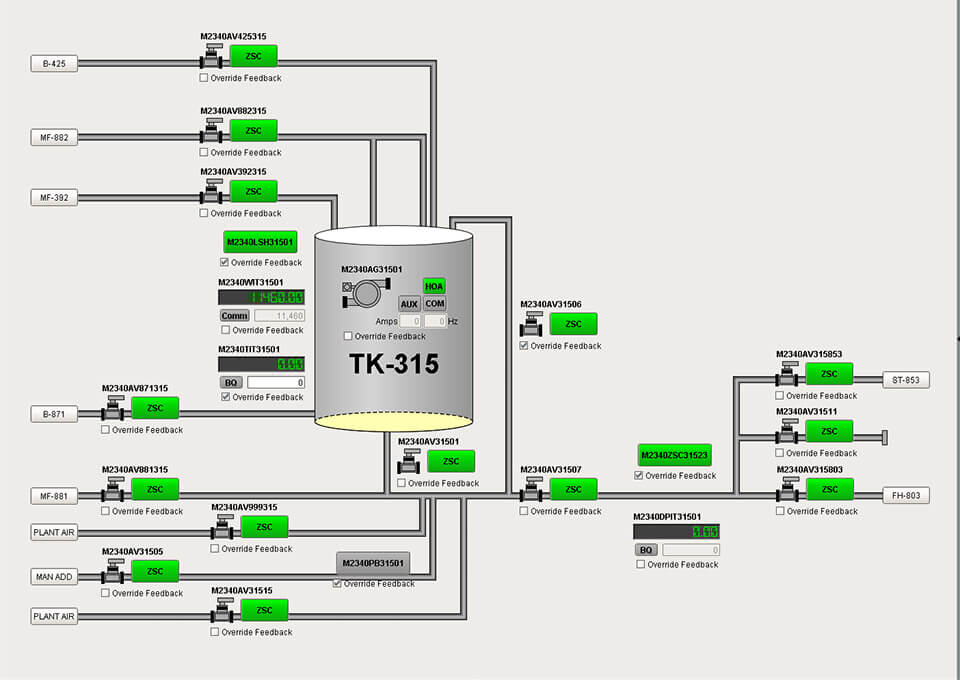

Remote FAT was executed using a simulation of the plant environment. The simulator is essentially a set of hardware consisting of PLCs and Ethernet switches, and a custom software application that was developed by A&E to mimic the customer’s plant devices (valves, pumps, motors, transmitters, etc.). The simulator was developed using Inductive Automation’s Ignition software. VMware was utilized to create the same production level server architecture that exists at the plant.

The process to perform remote FAT went like this:

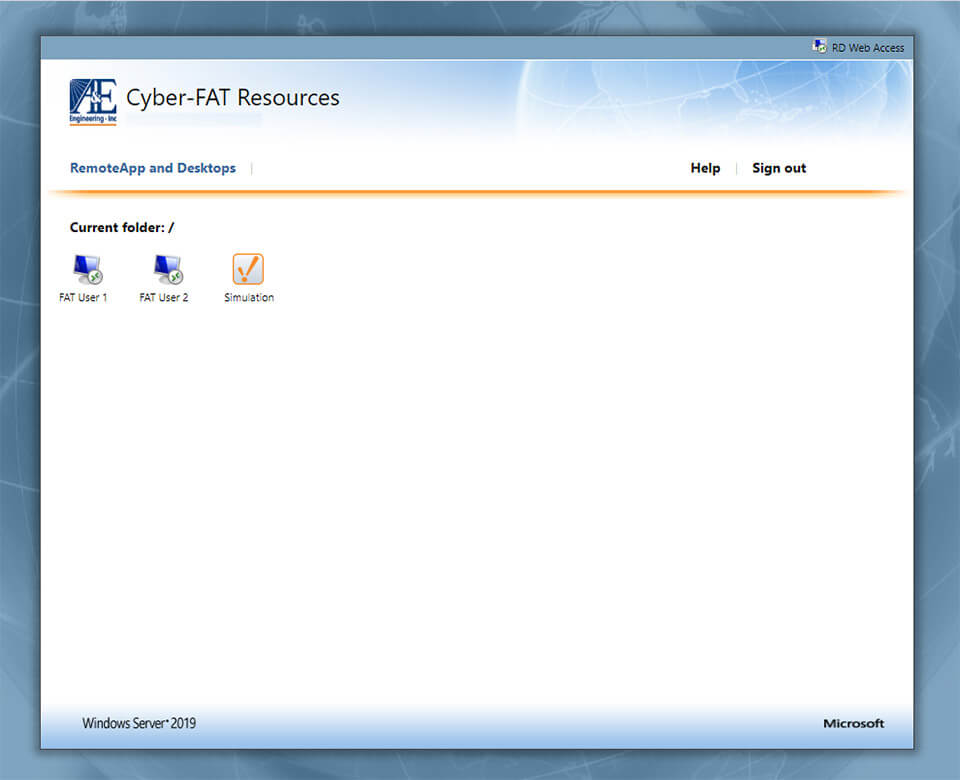

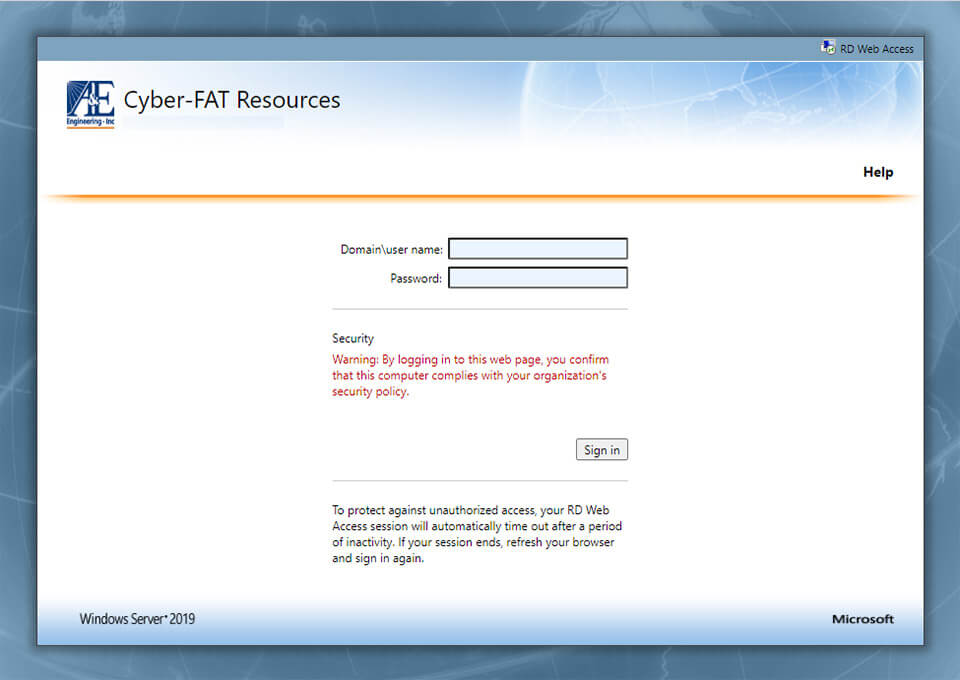

- The customer connected to A&E’s remote FAT system and logged in (from their own PCs).

- The customer used RDP (Remote Desktop Protocol) to open multiple screens from the simulation system: (1) the HMI screen and (2) the simulator screen.

- The customer ran through a jointly-developed FAT script to inject failure modes (e.g. fail valve, fail motor) and observe/analyze how the automation software responded to these failures.

- Microsoft OneNote and MS Teams were core to the communication process between client and A&E during testing. OneNote was used to capture change requests and bugs, while Teams was used to discuss what was happening during FAT in real-time.

- When an issue popped up, A&E could watch exactly what the customer was doing and take control of the system if needed.

- A&E was able to fix bugs and respond to change requests as they were coming in.

Software Developed

- Batch automation software

- Plant simulator

- Remote FAT software

Hardware Utilized

- Allen-Bradley PLCs

- Cisco Ethernet switches

- Dell host servers