![]()

Automotive

Industry

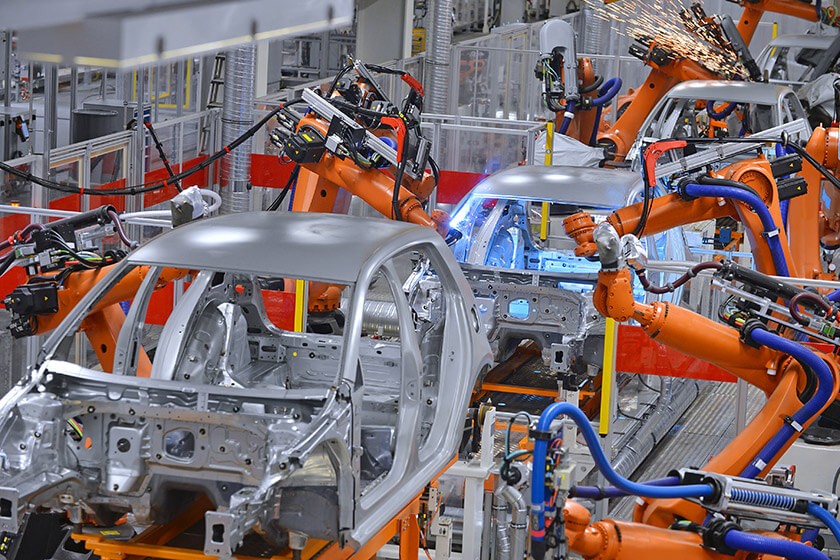

Innovating the automotive space

How We Can Help You

- Production capacity improvements & OEE improvements

- Turnkey automation system design, implementation & installation

- Obsolete automation system upgrades & conversions

- Digital transformation (cloud, analytics, simulation)

Capabilities

Well-Versed in Automotive Production

- Tier 1 & 2 manufacturing

- Body-in-white

- Paint

- Final assembly

- Logistics

- Energy

- Environmental

Design, Development & Deployment

- Downtime analysis & OEE improvement

- PLC/operator panel/HMI/SCADA programming

- Control panel assembly & wiring, including UL 508A & UL 698A compliance

- Virtual commissioning

- Production commissioning & support

Automation Equipment

- Paint shop process automation (air houses, paint lines, etc.)

- Robotic cells (e.g. sealer, wax)

- Robot cycle time analysis & optimization

- Stacker (ASRS) automation

- Automated conveyor systems

- Vision systems

- Motion control & servo systems

- Collaborative robot deployment

- Machine safety upgrades

- Body tracking systems

Project Management & Oversight

- Delivery of complete turn-key equipment automation projects

- GC & electrical contractor licenses held in multiple states

- Construction management

- Design & construction in hazardous & general-purpose locations