We look forward to speaking with you.

A&E Engineering Case Studies

-

Greenfield control system automation for automotive plant – paint process air houses

-

Manufacturing Control System Upgrade – Batch Process Automation – Liquid Ingredients

-

Oil Delivery Control System Upgrade at a Baking Facility

-

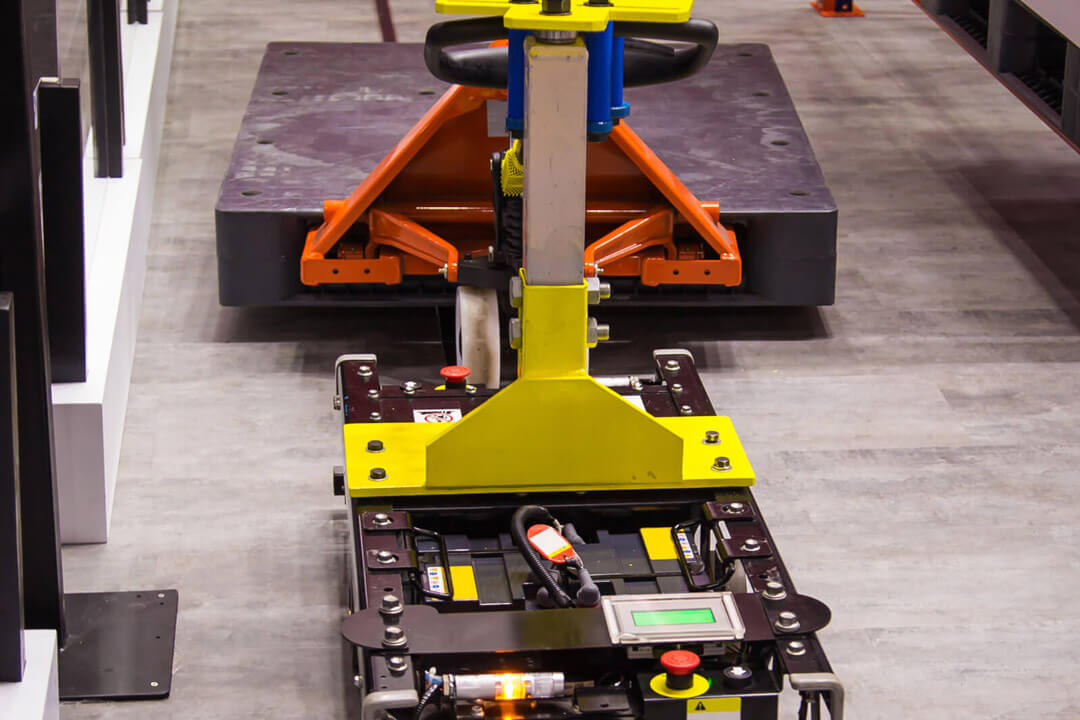

Factory Automation – Assembly Line Capacity Expansion

-

OEE/Downtime Monitoring and Reporting System for a Food & Beverage Plant